Standard manufacturing practices

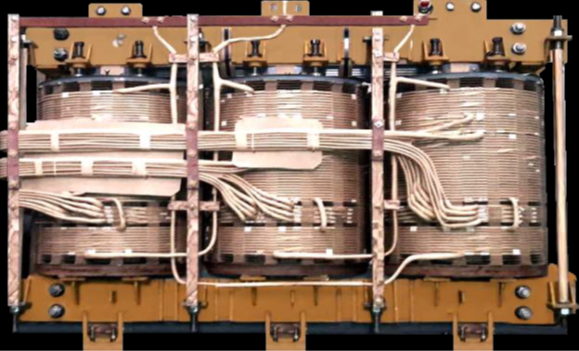

- KPEL use only pre-compressed board material for insulation.

- Axial and radial banding for sturdiness

- Interleaved disc winding for 33 KV CLASS Transformers.

- Layer type of winding for LV and HV coils for better impulse voltage distribution.

- Proper distribution of clamping force for better clamping of windings.

Static compression of winding

Defined Routing of Tap and Line leads for better voltage distribution

- Pre shrinkage of coil, smooth control of shrinkage force.

- No further shrinkage of windings under short circuit forces in the system.

- For core coil assembly, Pre compressed press board material/supreme grade insulating material is used.

- Silver coated tap switches for high current transformers and linear tap switches.

- Taps at winding middle for better ampere turn distribution and increased short circuit withstand.